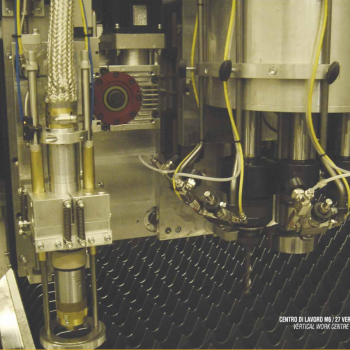

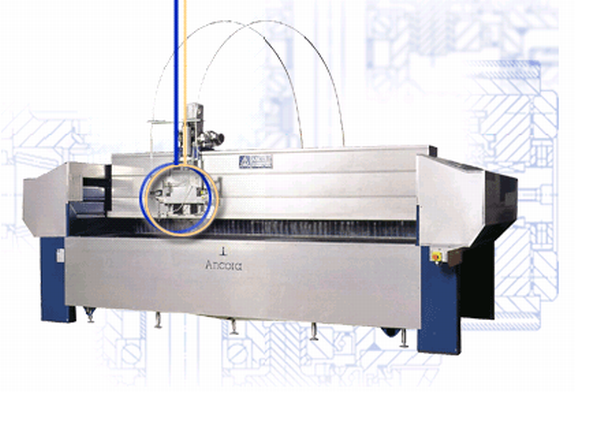

Sheet metal processing

Sheet metal processing with thermal cut:

plasma, oxyfuel, laser.

The strenght of this system is to propose a tested and user-friendly user interface and a PLC used “as it is” or customized for further specific functions of the constructor.

Another strenght of the configurability of the system is the wide choice of operator panels allowing the constructor to cover market segments with the best price/performance products.

The ISO programming language allows the programmability of the CN with the most used sheet metal CADs.

Available options:

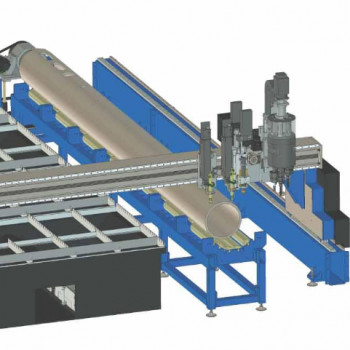

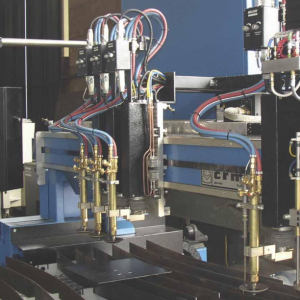

- One or more plasma torches combined to one or more oxyfuel torches

- Double plasma for symmetrical or parallel double cuts

- Marker function with plasma or external units

- Integrated torch height regolation

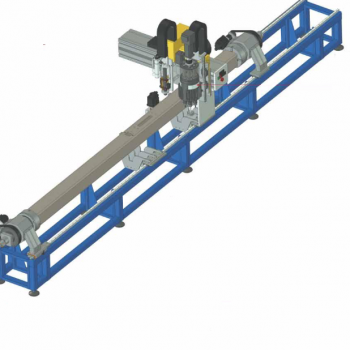

- Tube cut

- 3D Cut with several geometric libraries based on the mechanic configuration

- One or more Gantry axes couples

- Multitool spindles handling

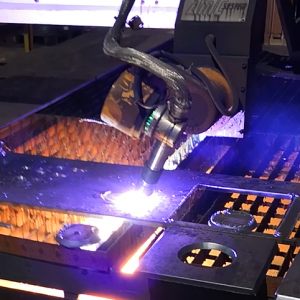

Plasma

Wide selection of individual/multiple torch. Internal/External torch regulation mode. Holes management. Gas-consolle management. Multiple focus function mode with latest focus-function memory. Cut charts management.

Laser

Optical collimator management. Breakthrough mode management. Runtime and edge modulation. Auxiliary axis of optical on CO2 laser path compensation.

Oxyfuel

Multiple torches. Thickness/pressure management. Buoyancy breaking-through. Distance sealing programmable torches with the exception of inert torches.

Stamping

Management of indexed heads. Dedicated cards [schede mazza].